PLASMA CUTTING

WELCOME TO LASER KRAFTER

INNOVATIVE LIGHTING, PRECISION CRAFTSMANSHIP.

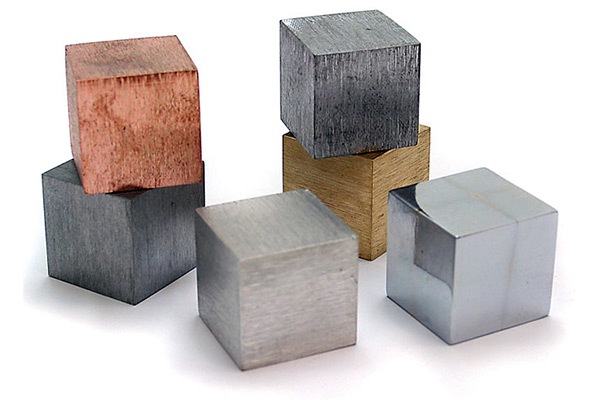

Plasma cutting is a process that uses a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials like steel, stainless steel, aluminum, brass, and copper. The plasma arc melts the metal while the high-speed gas blows away the molten material, creating a precise cut.

CNC PLASMA CUTTING MACHINE

At Laser Krafter, we also have a CNC Plasma Cutting Machine, a computer-controlled cutting system that utilizes a high-velocity plasma arc to precisely cut through electrically conductive materials. This advanced technology is designed for efficiency, accuracy, and versatility in metal fabrication.

MACHINE SPECIFICATION

Plasma cutting Power: 2238 Watt

Working Area: 1,500mm x 3,000 mm

Maximum Speed(m/min): 20

Cutting Tolerance: ±0.38 mm to ±1 mm

CNC Plasma Cutting MATERIALS

We can cut following materials types with the mentioned thickness;

- Mild Steel – 16mm

- Stain less steel – 8mm

- Aluminum – 3mm

- Copper – 3mm

- Brass – 3mm

We can handle sheets up to 1525mmx3050mm

Why Choose Our CNC Plasma Cutting Machine?

✅ High-Speed Cutting – Delivers faster cuts compared to traditional methods.

✅ Precision & Accuracy – Computer-controlled for intricate and detailed designs.

✅ Versatile Material Handling – Cuts through a wide range of metal thicknesses.

✅ Cost-Effective – Minimizes material waste and reduces processing time.

✅ Ideal for Custom Fabrication – Perfect for industrial, automotive, construction, and artistic applications.

USE OF PLASMA BEAM CUTTING

Laser Krafter used plasma torch cutting for many types of metals cuttings. Cutting master use this modern technology for the following particulars which are mentioned below:

- Islamic calligraphy

- Stairs handles designs

- Metallic Doors designs

- Chairs designs

- Metallic decoration pieces